A fan clutch is a thermostatic coupling device controlling the engagement of the electric cooling fan, relieving unnecessary load on the engine. As temperatures increase, the clutch engages so that the fan is driven by engine power and moves air to cool the engine.

It is integrated in the fan blades and is located frontally in the vehicle. The fan clutch can be driven by a belt and pulley or directly by the engine when mounted on the engine’s crankshaft. Depending on the cooling needs, the fan can be engaged partial or full.

Most fan clutches are viscous or “fluid” couplings, combined with a bi-metallic sensory system similar to that in a thermostat. Some clutches are electronically controlled (instead of bi-metallic strip). These provide the potential to control the level of some factors, which might include engine oil temperature, transmission oil temperature, coolant temperature, AC system pressures and ambient air temperature.

Viscous fan couplings (also known as viscous fans or viscous fan clutches in the aftermarket) are used on vehicles (cars and trucks) with inline engine positions, mainly rear wheel drives. These fans are needed at slow speeds and while idling. A faulty fan can cause an engine to overheat while idling or in heavy traffic, or poor mileage and loss of horse power.

Effective dissipation of heat from vehicles requires not only high-performance radiators, but also fans and fan drives to supply the cooling air as efficiently as possible. The aerodynamic matching of cooling module and fan ensures efficient engine cooling at optimum cost.

LOCATION

Viscous fan couplings are located between the water pump pulley and the radiator.

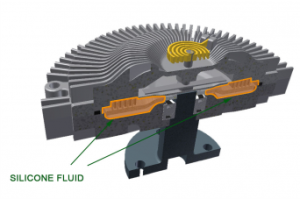

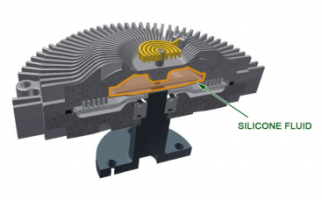

A bimetallic or an electronic component controls the fan, depending on the ambient temperature. The purpose of the Visco clutch is to provide traction to the fan wheel and to influence its speed. If no cooling air is required, the Visco clutch switches off and continues to run at a lower speed. The Visco clutch is triggered by a bimetallic element that is exposed to the ambient temperature. A pressure pin releases a hole and silicone oil flows from the supply tank to the working chamber. The drive torque is transferred to the fan; the continuously variable speed of the fan is set automatically on the basis of the operating conditions by means of wear-free fluid friction.

The electrically triggered Visco clutch, on the other hand (see figure), is controlled directly by sensors. A regulator processes the values and a pulsed control current carries these to the integrated electromagnet. The defined guided magnetic field regulates the valve which controls the internal oil flow via an armature. An additional sensor for fan speed completes the regulator circuit. This increases the sensitivity with which the fan is turned on and off. Controlling the cool air flows as needed while minimising the development of noise and the load reduces the fuel consumption and the impact on the environment.

FUNCTION AND ASSEMBLY

– Controls fan speeds to aid engine cooling

– Aids in the efficiency of the engine by engaging the fan, when necessary

– Reduces load on the engine

Either assembled directly to a flanged shaft mounted onto the pulley of the water pump, or alternatively it can be threaded directly to the water pump hub.

MECHANISM

Electronically controlled Visco fans are used in a wide range of vehicles—from heavy trucks to vans and SUVs with powerful engines. They detect all relevant temperature values for cooling and air conditioning purposes and set the exact required fan speed. This ability to deliver precision, on-demand control while ensuring rapid response times and low idling speeds when the drive is deactivated have a positive influence on fuel economy, driving comfort, and noise emissions.

This product is based on the bimetal sensor located at the front of the viscous fan. This sensor expands or contracts, depending on the temperature imparted through the radiator. This intelligent component improves engine efficiency by regulating the RPM of the engine fan and cool air supply.

At cold temperatures:

The bimetal sensor contracts closing the valve, so the silicone fluid remains in the reservoir chamber. At this stage, the viscous fan coupling is disengaged and turns at around 20% of the rotation speed of the engine.

At operating temperatures:

The bimetal sensor expands, rotating the valve and allowing the silicone fluid to move through the entire chamber to the outer edges. This generates enough torque to drive the cooling fan blades at engine operating speeds and remain at a consistent temperature. At this stage, the viscous fan coupling is engaged and turns at around 80% of the rotation speed of the engine.

FAILURE, COMMON CAUSES

It is good practice to always check the condition of the viscous fan coupling when the water pump is replaced. A worn coupling will directly affect the water pump’s lifespan. A failed viscous fan coupling can stay stuck in the engagement position meaning it will always run at 80% of the engine rotation speed. This can cause disruption with high noise and vibration, making a loud whirling sound as the engine is revved and will increase fuel consumption.

On the other hand, if the viscous fan coupling fails in the disengaged position, it will not draw air through the radiator. This in turn will lead to the engine overheating as the cooling process is disrupted.

– Leaking silicone fluid, disengaging the fan coupling.

– Bimetal sensor losing its properties due to surface oxidation, causing the coupling to be stuck disengaged.

– Bearing failure, although uncommon can occur if the viscous fan coupling has not been replaced after high mileage. This results in the condition of the blades deteriorating.

MARKET POTENTIAL AND SALES OPPORTUNITY

Being a high-value ticket item at OE level, dealers service only a very limited business while the aftermarket for this product is shared between 8-10 suppliers. Although these suppliers have gained a small foothold within the market, none of them offers a full range.

Important brand names for the viscous fan coupling are: Behr(Hella), Mahle, NRF, Nissens, Dasis.

When replacing the water pump, it is best practice to check that the viscous fan coupling is operating correctly as well.

In the current market this part could be overlooked during the replacement of the water pump. This could lead to factors missing out on a sales opportunity, whilst the vehicle owner potentially would have to pay a second labour charge to replace the coupling at a later stage.